Line AKL & AKLJ

Line includes:

- feed-in table with side guides

- straightener with 9 rollers of OD 100 mm

- pull unit with OD 130 mm rubber coated rollers

- slitter unit with suitable amount of blade pairs and guillotine type cutter

One side of feed table guides is fixed, other adjustable by hand wheel to match the coil width. The 4 upper straightener shafts are adjustable on the operator side using hand-wheels with scales. The 5 lower shafts are adjusted with screws on the unit body. The slitter is driven via roller chain by the pull unit motor. The locating and fixing of blades is manual. The guillotine has two sided blades. It can be built operating with either stationary web or as “flying cut-off” system.

Servo-drives for all operations – straightening, pulling, slitting and cutting. All electrical components are in one single electric cabinet. Controls from separate control panel.

Type AKL: Cutting&slitting machine with stationary web system.

The web feed is run down to full stop for cutting and then accelerated again.

Type AKLJ: Cutting&slitting machine with “flying cut-off”.

The web feed is slowed down but not stopped for cut-off time.

Technical Specifications:

| Sheet width | 1 300 / 1 500 mm |

| Sheet thickness (EN10130) | 0,4 – 3,0 mm |

| Drive speed of sheet, standard | 0 – 40 m/min |

Machine is controlled by Windows CE HMI panel with Lenze PLC runtime.

Control Panel Specifications:

- 10” TFT colour touch screen, resolution 640×480

- Available display languages: Finnish, English, Russian, Czech, Romanian

- SD memory card for program storage

- Ethernet connection for remote maintenance over the internet (optional)

Control Panel Functions:

- Emergency stop reset button/indicator

- Emergency stop button

- Start/Stop button

- Speed potentiometer

- Automatic mode speed source selection button/indicator (used with recoiling)

Software:

- Manual drive with remote manual controller (buttons for sheet forward, backward and cut)

- Uncoiler manual / automatic control

- Feed table manual control

- Single cut mode with single cut length and quantity

- Program run mode, 10 rows for cut lengths and quantities. Programs can be named and saved for further use. Start row can be selected.

- Length sorting option

- Sheet move speed can be adjusted with speed potentiometer during manual and automatic modes

- Lift table manual and automatic control

- Selectable sheet support (double sheet support with flying cutter)

- Flying cutter selection (optional)

- Recoiling selection (optional)

- Automatic split waste elimination (selectable)

- Automatic split tool setup position search (selectable)

- Automatic sheet feed selection

- Settings menu for machine parameters (password protected)

- Service menu (password protected)

- Emergency stop switches

- Protection in automatic mode, light barriers (option)

- “Flying” cutter area protection fences

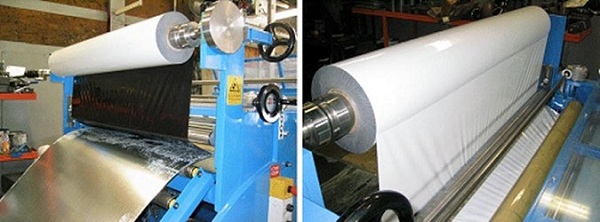

Protection film laminator:

Digital read-out for slitter blade positioning: